Today I am in beautiful Latvia. The sailing boat of a friend of mine is stored at the Pavilosta Boat park shipyard. First, we will carry out some maintenance before we go out sailing. We are experienced sailors, but now we are facing a real challenge. Because, how long has the anti-fouling paint been on the surface? We have no idea. If it was applied only two years ago, there is no need, and it certainly would not be environmentally friendly to apply a new layer now. But if the boat is going to be in the water for another two years with too old a layer of anti-fouling, the next servicing will be a lot more expensive.

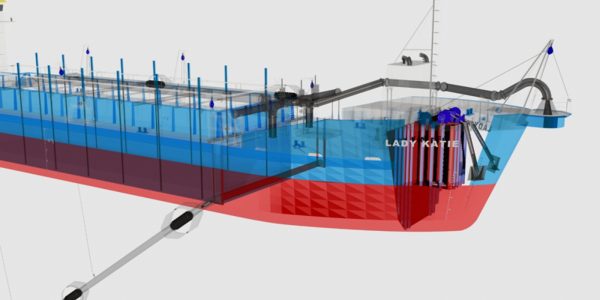

This is exactly the lack of up-to-date information I often encounter in my work. Shipyards run into outdated information at almost every update of, for instance FPSOs. Often there is information available about these big ships, but because of the updates of the ship, the information frequently no longer corresponds with the ‘as built’ situation. It is often a time consuming job to turn the ‘as built’ situation of a ship into ‘up-to-date’.

During my twenty years of experience in the maritime industry, I have seen that when the ‘as built’ drawing has been composed, it is often difficult to work with this kind of information. Simply because everyone looks at a ship from a different point of view, concerning new parts to be installed. A purchaser for instance, would like to know what the new pump on a drawing is going to be used for, the engineer wants to know how it will be mounted and a painter is in search of a RAL colour coding. As a consequence, dozens of emails are sent throughout the organisation about just one little part of the ship. Just think how many emails it would take to conclude a complete update, let alone the construction of a ship!

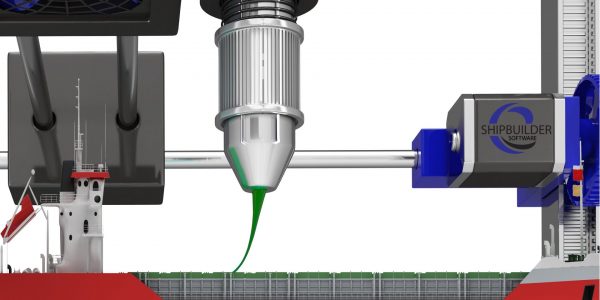

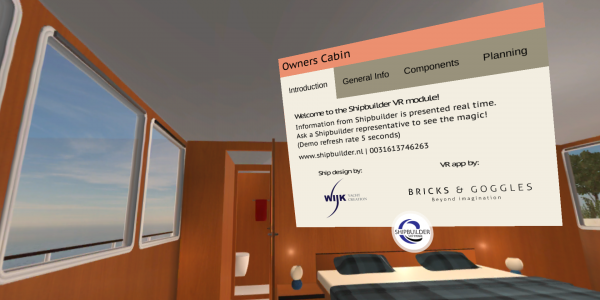

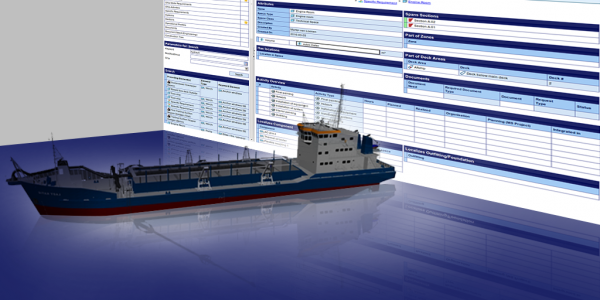

Using all this experience we have created Shipbuilder, to give insight in the construction, maintenance and even the dismantling of ships. Shipbuilder as such offers an enormous added value, by single truth approach in a multi-dimensional environment. In simple terms, for every part there is a useful track record in Shipbuilder, to which everyone, involved in the ship’s construction or update, can contribute. If the purchaser cannot find pumping information in the purchase specifications of the pump, he will consult the engineers. Subsequently he will add the exact specifications to the pump. This information also has added value for the other engineers. The software focuses on interaction between the various disciplines that are involved with the construction of a ship. Due to real time sharing of information, the quality of the entire project is rapidly increased.

Looking at the surface of the ship, I see Shipbuilder before me. There I would have found when the anti-fouling was applied last, which type it was and which maintenance intervals were recommended. I even would have received an automatic message about the renewal of the anti-fouling and would have stepped on board without a worry. From now on, the owner of this little sailing boat also keeps his data in Shipbuilder.