Speaking: Marc Derks and Yves de Vos (Damen Shiprepair Rotterdam)

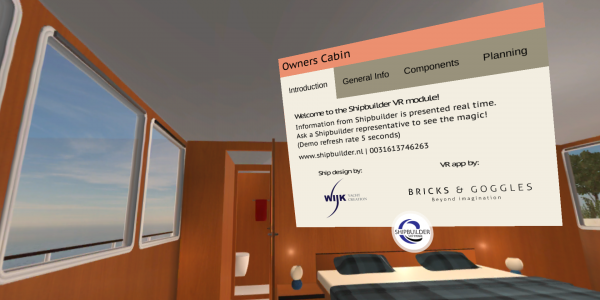

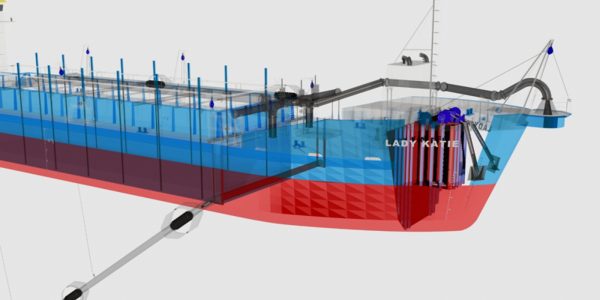

“With such a large project, you will have a gigantic amount of data. A professionally organized maritime data management program will be very welcome.” Meet Marc Derks, Senior Project Manager at Damen Shiprepair Rotterdam. He also worked on the upgrade of the Petrojarl 1. This FPSO is 215 meters long and 32 meters wide. A major challenge. Also at the table Yves de Vos, Interface Coordinator: “With a small investment we could instantly import data from all kinds of programs and we could make relationships in complex data. We could do a lot of work faster and with less people. We need to expand this success further.”

1. The time of Excel has passed, choose an intelligent maritime data management program

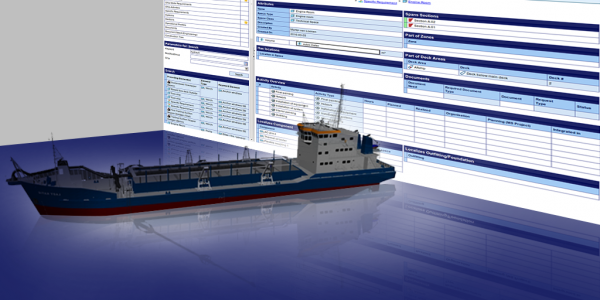

They love to tell you how they have handled the data management with the Petrojarl 1 professionally. Marc: “A lot of shipyards still work with Excel. This goes well until someone becomes ill. Or when there appear to be multiple versions. Or when internal relations need to be made between 22.000 items/tags with a size of 1 Terabyte which also need to have sub relations. In this case Excel-data becomes unreliable.” Yves adds: “Excel is to calculate and no carrier of complex data. My message to everyone that wants to learn from this story: start looking for an intelligent maritime data management program. In Shipbuilder we find a reliable and intelligent tool.”

2. Flexible data management programm required for competitive position shipyard

Within the project, Yves was responsible for the design of Shipbuilder. “I find it a flexible program which is designed for the shipbuilding industry. The modification and upgrade of the Petrojarl 1 had highly variable dimensions which caused the data structure to sometimes be greatly adjusted. I had it done in three days. In comparison; with other programs this took me more than three weeks. Let alone when you’re talking about a program like Excel, which simply had not worked. Practice has shown: a flexible maritime data management program is required for business and competitive position of a shipyard.”

3. Workfloor is leading in digitization: acceptance rate workfloor up

Marc is a great supporter and pioneer of digitizing shipbuilding of which he gets the space at the innovative Damen. “Digitization is being implemented globally in various ways. What I often see is ERP programs in which everything is documented by cost code. This does not match with the workfloor where technical and logistic structures are required. My advice is to find a program which does match. With the upgrade of the Petrojarl 1 we have successfully used Shipbuilder, because it could process every kind of structure at the same time.” Yves adds: “I noticed some terminology on the workfloor was different than in Shipbuilder. I adjusted this in no time. With that flexibility it’s a 100 percent guarantee the software matches the workfloor which naturally causes the acceptance rate of users to be higher. With each other we had a hold of that 1 Terabyte of data and the project.”